Fluid Sampling

Whether you’re a regular fluid sampler, or only beginning, we provide you with everything you need to know to order, take and send a sample.

ALREADY SAMPLING

You may already know how to take a sample as well as own your own sampling gun and tubing. Thus, when you complete the online ordering form make sure you omit a sample gun and tubing from your order. You can use the supplies you already have.

BEGINNING SAMPLER

If you’re new to the sampling process, you most likely need a full kit. When you complete your online ordering form make sure you check the box that indicates you need a sample gun and tubing with your order kit. This is the only time you will need to purchase these supplies. They are reusable.

FLUID ANALYSIS SERVICES

The productivity of your machine starts at the NMC Technologies’ Fluid Analysis Lab, Nebraska’s only full-service fluid analysis laboratory.

NMC Technologies’ skilled technicians analyze your machine’s vital fluids. We find problems before they cause downtime. Depending on the analysis, some results can be provided within 24 hours.

OIL ANALYSIS

- Spectral Analysis monitors wear by detecting, identifying, and assessing the amount of additives and type of wear metal elements in the fluid, confirms if the correct oil is being used and whether fuel or oil is entering from another compartment.

- Oil Cleanliness Analysis uses a Particle Count test for non-engine oil. It detects both metallic and non-metallic debris generated by wear, as well as outside source contaminates.

- Oil Condition Analysis determines loss of the oil’s lubricating properties and whether the oil is performing up to specification during the entire oil change period using an infrared analysis instrument.

- Oil Contamination Analysis determines the presence of external contaminants. Fuel, water, or glycol contamination indicates problems exist that require immediate correction.

PERCENT FUEL

NMC Technologies recently made a significant investment for Tier 4 engines with the purchase of a PerkinElmer Clarus 500 GC. With this specialized equipment, viscosity testing, and our knowledgeable lab technicians, we can determine if fuel problems exist in a diesel engine, helping to eliminate costly downtime and repairs.

COOLANT ANALYSIS

High engine operating temperatures mandate proper cooling system maintenance. Problems in your cooling system can spread throughout your engine, transmission, and hydraulic system, yet cooling system maintenance is often neglected or overlooked. NMC Technologies’ Coolant Analysis detects potential problems before damage occurs. A two-level analysis verifies the proper make-up of your coolant and diagnoses the condition of your cooling system. This allows you to correct coolant deficiencies inexpensively before costly problems arise.

- LEVEL 1: is a basic coolant maintenance check which determines if the coolant has the right balance for proper heat and corrosion/erosion control. Glycol level (freeze & boil protection), SCA concentration (corrosion/erosion protection), pH (acid level), and conductivity are tested.

- LEVEL 2: is a comprehensive cooling system analysis. It includes all Level 1 tests and goes one step further by completely analyzing the coolant and its effect upon the cooling system. The tests identify metal corrosion, other contaminants, and built-up impurities which point to corrosion and scaling problems before they lead to more costly repairs.

FUEL ANALYSIS

Fuel contaminates can stop a machine cold. NMC Technologies’ lab has the ability to check for fungus and bacteria that can cause fuel filter plugging. If you think oil or coolant are entering your fuel, our investment in the proper equipment can detect these contaminates.

Download our Fluid Analysis Brochure

FLUID ANALYSIS LAB

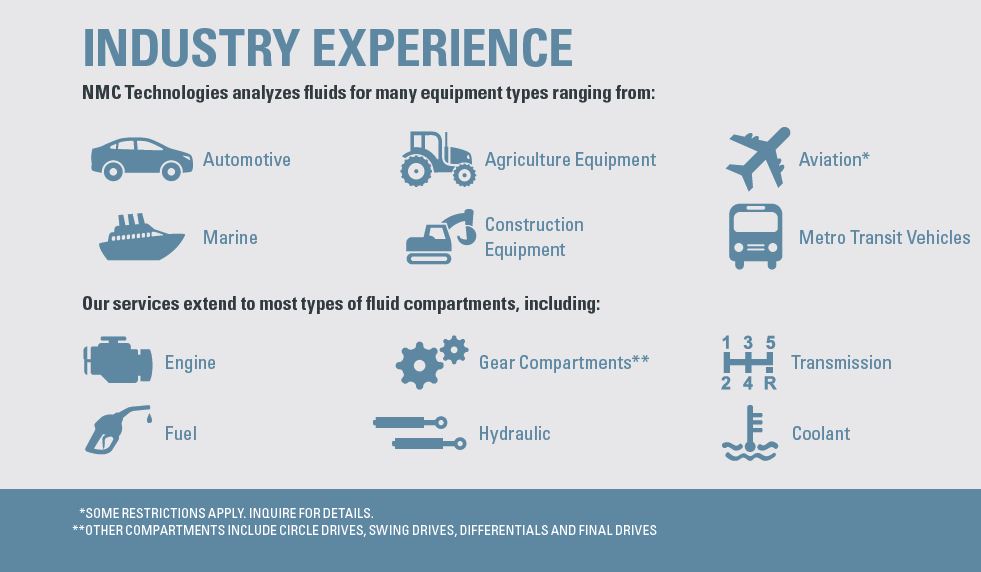

The NMC Fluid Analysis Lab contains state of the art equipment to accurately and efficiently test your fluid samples. Tests can be performed on any equipment type or compartment. Click here to take a look inside our lab!

YOUR RESULTS

Most oil analysis results are available in 24 hours after receipt of the sample. Fuel and coolant results are typically available within 72 hours to one week. Additionally, each sample receives individual interpretation. We communicate your results in easy to understand language and we provide you with recommendations. You can receive your results in a number of ways including online, via email, phone or fax.